What is Diamond Drilling?

Diamond Drilling

Precision Diamond Drilling is a process of creating a clean cut holes

Sizes from 10mm-700mm in diameter & drilled to any required depth.

Diamond Drilling is used in all building concepts.

The advantages of Diamond Drilling

- Dust free

- Vibration free

- Quiet

- Clean cut

- Cost Effective

- Diamond Drilling has less chance of affecting structural integrity.

- Water control - Slurry attachments are used to create a mess free area whilst drilling but still using the required water to be able to drill through even the hardest material.

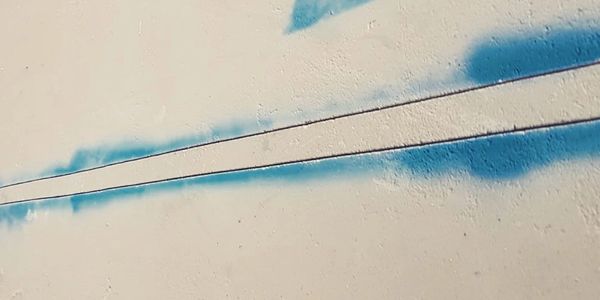

Wall and Floor Concrete Chasing

Wall and floor Chasing is completed by cutting two parallel lines up to the depth of 40mm to accommodate conduit piping in various materials.

For example:

- Concrete

- Standard brick and Engineering Brick

- Flint and concrete block.

- Brick and Block

Chasing is used in all building concepts

Mainly to conceal pipework or electric cables.

Chasing is relatively Dust Free, Vibration Free and Cost Effective.

Wall and Floor Sawing

Wall and floor sawing is the use of a diamond circular saw blade to mount on to steep vertical walls or horizontal flat surfaces to form precise cuts and dimensions.

This concept is regularly used for door and window openings in reinforced concrete walls or floor.

The advantage of wall and floor cutting are:

- Accurate cuts

- Cost effective

- Wet cutting with a dust free environment

Our recent Diamond Drilling & Sawing Projects

2025

Diamond Drilling & Sawing

Diamond Drilling in residential homes

We are in our third year of completing core drilling in residential flats for the install of sprinkler systems in and around the .

We have provided the client with the best set up for zero water damage and we have had many compliments on how clean our work has been throughout.

Our experienced diamond drilling teams are able to complete this with ease and also be very friendly and courteous to all the residents they meet.

Receiving many compliments from the main contractor

Floor boxes in concrete floors

We were required to create multiple floor boxes and chases to internal concrete floors using handheld saws and chasing equiptment.

All work was completed outside normal working hours due to it being a live working environment with noise restrictions.

Working sections of the building were kept away from the public.

Stitch Drilling

In this stitch drilled picture one of our diamond drilling operatives creating holes by handheld drilling with dust extraction control.

Work was completed trhoughout the night due to noise restrictions.

This opertives worked in teams to diamond drill and series of holes throughout the project, working closely with the on site supervisor.

Operatives leave their drilling areas clean, tidy and safe for other workers.

Stadium core drilling

We have recently completed work on Birmingham City and the Aston Villa Stadium.

Core drilling various sized core holes using a RIG and motor throughout the stadiums.

All areas were left spotless after drilling was completed, using our wet vacuums that are provided to all of our operatives.

Core drilling was required within a tight timescale.

Brick Work Openings

Our regular client required openings at a specific size in Brick Walls.

The material we were cutting was Brick.

After completion our client emailed that they were extremely satisfied on how this was completed and remarked on how clean we left the cutting area.

Curved Trench - Selfridges Birmingham

Our Client requested a curved channel in concrete floor for a retail shopping center in Birmingham. We first visited site to determine the exact curve they were looking for and to determine the depth they would like the channel to be. When we visited site we also looked into the Method of how we were to complete this curved shape in a furnished shop and how to minimize dust and noise. This work was agreed to be completed over night and dust suppressed hand saws were used.

Expert Diamond Drilling and Sawing Specialists Contact: info@edsdiamonddrilling.com

Cookies

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.